Top picks for warehouse efficiency

Warehouses come in all shapes and sizes, from high-volume distribution centres to more specialised storage spaces. They all have one thing in common: the constant need for safe and efficient operations.

Most warehouse workers know the frustration of watching their team struggle with awkward loads or time-consuming manual processes. Getting the right forklift attachments not only improves productivity but can also help prevent injuries and equipment damage – two things that can lead to costly downtime.

Let’s look at six practical attachments that can make a real difference in your day-to-day operations:

Top 6 picks for warehouse efficiency

- Fork-Mounted Poles

If you’ve ever worked with rolls of carpet or wire coils, you’ll know how tricky these materials can be to handle. Fork-mounted poles take the stress out of moving rolled materials. They support the full length of the roll, keeping it stable during transport. That means no more worrying about materials sliding off or workers having to manually steady the loads.

This attachment is valuable in warehouses where rolled materials are handled daily. It means one person can safely move large rolls that would need two or three workers to handle manually. This reduces the risk of strain injuries while also speeding up operations.

- Fork-Mounted Drum Lifter

Moving drums and barrels manually can create delays. Fork-mounted drum lifters remove the need for manual handling, so one operator can safely grip and move heavy drums. This means fewer people needed for drum handling, less strain on your team and a lower risk of spills or accidents.

For those handling liquids or storing chemicals, these attachments are essential. They prevent common issues that go alongside drum handling, like back injuries from manual lifting, damaged drums from incorrect handling and potentially dangerous spills.

- Combi Skip

The combi tip is a game changer when it comes to waste management in tight spaces. Its unique four-way entry base makes it easy to manoeuvre in confined areas, so you can access and move it easily even in the most cramped warehouses.

It’s also flexible: the standard model is manually operated, but you can choose to upgrade with an automatic tipping conversion kit. This means operators can empty the skip from the safety of their forklift without having to get out of the cab – improving both safety and efficiency. Its fully seam-welded design means it can contain liquids, while the secondary locking mechanism prevents accidental damage.

- Multi-Cylinder Gas Bottle Handler

If you’re handling a lot of gas cylinders, the multi-cylinder gas bottle handler is an essential tool that can save you both time and effort. Instead of moving cylinders one by one, this attachment allows you to move several at once, dramatically cutting down transport time.

The design keeps cylinders secure and stable during transport, preventing movement that could lead to damage. By reducing handling time, it improves productivity, as well as ensures compliance with the strict safety standards needed for handling gas cylinders.

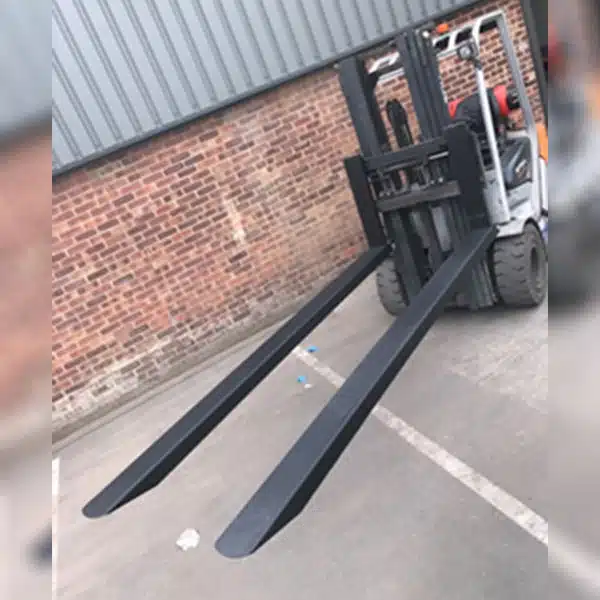

- Forklift Fork Extensions

Handling oversized loads that don’t quite fit standard forks is a common issue in a lot of warehouses. Fork extensions are the simple solution to the problem, giving you the extra reach you need while spreading the weight evenly to stop tipping. This reduces the number of trips needed for transporting materials and means more stable, safer lifting.

Fork extensions are especially helpful in lumber yards or construction material warehouses where long loads are common. They mean you can safely handle materials that would otherwise require special equipment or multiple trips, saving both time and money.

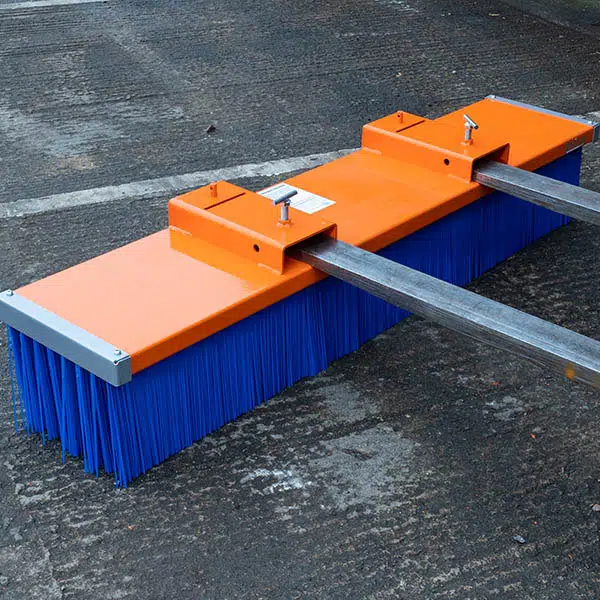

- Forklift Sweeper Brush

A messy warehouse floor doesn’t just look unsightly, it can also be a major safety risk. Sweeper brush forklift attachments mean you can clean as you go, catching debris before it becomes dangerous. It’s especially useful in high-traffic areas where cleaning staff might struggle to keep up.

In busy warehouses, a sweeper attachment can save hours of manual sweeping time each week. It’s particularly effective in areas where packaging materials, dust or dirt can accumulate quickly, helping you maintain clean and safe working conditions.

The practical benefits

The right attachments do more than just speed things up. They can deliver huge improvements across your operation:

- Cut down on manual handling and associated injury risks

- Help prevent common workplace injuries, saving time lost to accidents

- Make your existing equipment more flexible, saving on additional equipment costs

- Keep you compliant with safety regulations

- Save money by reducing the need for multiple pieces of equipment

- Improve staff morale by making difficult tasks easier and safer

Solving your warehouse challenges

Every warehouse has its unique challenges, but the right attachments can make them more manageable. Whether you’re dealing with traditional pallets or specialist materials, there’s always a solution that can help make your warehouse operations safer and more efficient.

Do you have a specific challenge? Let us help you find the perfect forklift attachment. With over three decades of experience, we’ve helped thousands of customers find practical solutions to their everyday challenges. We can even work with you to create a bespoke design tailored to your unique needs. Get in touch to find out more.

Back to all blog posts