Product Description

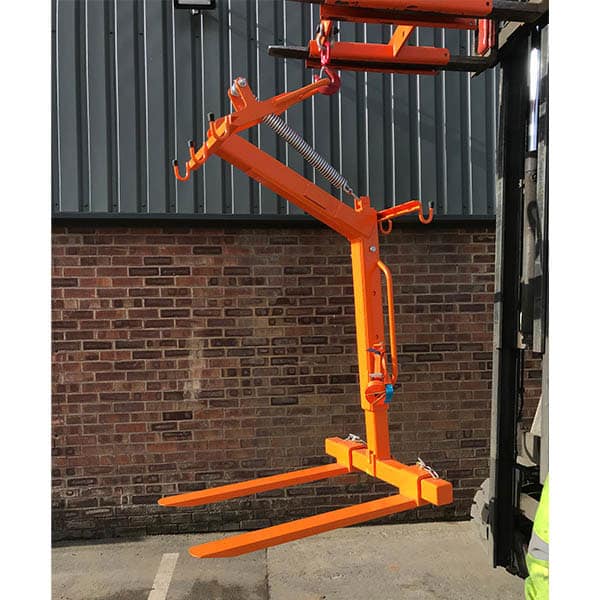

The Automatic Pallet Forks effectively convert an overhead crane into an effective pallet mover. There are many applications where fork trucks cannot be operated due to a lack of floor space for example high rise developments. Our crane forks are equipped with adjustable forks, height adjustment and an automatic balancing sprung head along with pre-fitted restraint net frame (net supplied separately).

Approximate lead time: Approx 2-3 days

Downloads

Specification Sheet (PDF)Product Variations

| Model | Weight (kg) | Fork Length (mm) | Fork Cross Section (mm) | Fork Opening Range (mm) | Load Capacity (KG) | Overall Height (mm) | Price | Qty |

|---|---|---|---|---|---|---|---|---|

| IPF-BOS-10-20 | 170 | 1000 | 100 x 35 | 300-1000 | 2000 | 1800-2500 | Call/Enquire for prices | |

| IPF-BOS-12-20 | 190 | 1200 | 100 x 35 | 300-1000 | 2000 | 1800-2500 | Call/Enquire for prices |

- Operation

- Maintenance

- Health & Safety

Operation

- Operate overhead crane / HIAB into position directly over the crane forks.

- Place the crane/HIAB hook onto the lifting eye of the attachment.

- Slacken the thumbscrews to position the forks at the widest possible distance apart to suit the pallet.

- Retighten thumb screws onto rail ensuring that they are adequately tightened and secure.

- With the pallet forks slightly raised, manually re-position the Pallet Forks to enter the pallet with the handles provided on the rear of the frame.

- Operate overhead crane / HIAB to enter the forks fully into the pallet.

- Once fully inserted into the load, place the safety strap around the load & secure.

- Lift the pallet clear of the ground and slide restraint net underneath. Attach to the six net hoops on the frame. Always use a restraint net when lifting overhead.

- When positioned correctly & secured, the load is ready for movement.

Maintenance

- The Pallet Forks should be inspected weekly for general condition with attention paid to: A – All weld points, B – Wear & distortion of thumb screws, C – Any damaged components, D – Lock & latches, E – Pivot points

- All bolts must be checked for tightness.

- The pivot bars must be kept greased.

- The spring should be oiled.

- Check the restraint net for damage and replace if worn.

- Damage or failure must be reported and rectified immediately prior to re-use of Pallet Forks.

- General surface rusting especially in the critical areas should be treated with proprietary inhibitors, primers and paint on a regular basis.

- This product is certified for six (6) months from the date of manufacture after which it is the customer’s responsibility to have the product re-tested at an approved testing facility or inspected and logged in a register by a competent person as advised by the HSE.

Health & Safety

- The manager of the department or section where the attachment is to be used must be responsible for ensuring the operators are fully conversant with the attachment, its operation & maintenance.

- Ensure both the crane and attachment can handle the intended load and its contents.

- Operators must keep clear of the mechanism whilst in operation.

- Do not shock load the attachment under any circumstance.

- In the event of failure during operation do not attempt rectification or re-operation while the attachment is off the ground. The attachment must be returned safely to floor level for inspection.

- Never drive at the product at an excessive speed as this may result in injury to the driver and/or damage to the attachment and Fork Lift Truck.

- Keep hands away from all moving parts.

- Spring loaded self-balancing head.

- Safety Net Frame

- Adjustable Height – Clear Height 1200-1900mm

- Adjustable Fork Widths

- Convenient Hand Holds.

- Painted bright orange for safety

Standard Features

- Restraint net – N.B The net is not certified or designed to catch a falling load, it is designed to withstand a partial collapse of the load.